BatteriesI'm always on the look out for small yet moderately powerful batteries to power the on board electronics. It's always a compromise between cost, weight, voltage and current capacity. I've been using the Lithium CR123As in pairs to give me 6V but the amount of current they supply is much more than I need and hence are unnecessarily large. 9V batteries are pretty good in price, voltage and current but are comparatively heavy ~45 grams. A stack of button cells generally cannot supply enough current to drive servo motors.

When cost isn't an issue and you are after minimal weight and maximum power density then I expect some of the tiny Li-po batteries are the way to go. But they do need a charger, are expensive and not readily available.

I came across this video a few weeks back, and finally had a go at pulling apart a 9V battery this week.

http://au.youtube.com/watch?v=tr5ZB1eFhwcJudging by the YouTube video comments a number of issues need to be looked out for:

- Only go for Energizer or Duracell alkaline batteries

- Don't short anything out while doing so.

- Wear gloves should you spill some acid

I only need 6V to power all the electronics so 4 of the cells are all I need. It also means that getting two 9V batteries I can make up three 6V battery packs. At only a few dollars per battery pack it means they are very affordable, and available everywhere. After removing the casing, connectors, and two cells the weight of the battery drops from 45 grams to 25 grams. In comparison a AAA 6V battery pack weighs ~44 grams, and AA battery pack weighs ~90 grams.

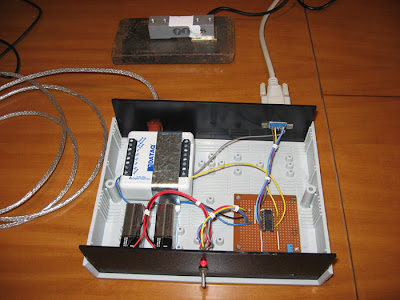

I just soldered wires to the contacts to make up the connections. I have started doing this ever since we found that some battery holders under G forces can easily loose contact. They powered the flight computer and servos just fine.

The small form factor means that they can be rearranged to fit the available space.

Flight Computer V1.6I've ordered all the parts now for the next iteration of the flight computer. This will be a slightly larger run of 20 compared to the 10 made for V1.5. I am waiting for all the components to arrive first in order to verify their dimensions before finalising the PCB. I'm also investigating a small and cheap G-switch option to trigger it rather than the commercial G-switch costing around $9. The PCB will be designed so both variants can be used.

The updated software is also almost finished. We had a request come in from a water rocket team (Oberon WR) who built version 1.5 of the FC but their servo was only turning only around 90 degrees even though the full range of movement was 180 degrees. We tested this with one of our cheap 180 degree servos and sure enough the full range was around 90 degrees. I checked the PWM signal on the CRO and the standard range of ~1ms to ~2ms was correct coming out of the FC. I updated the code to give a range between 0.5ms and 2.5ms and that gave the full range of the servo movement. If I have sent you a copy of the V1.5 code, I can send you the update if you have this issue. Other servos worked fine with the 1-2ms timing.

It seems that some servo manufacturers don't adhere to the standard 1-2ms for full range. This change will also be rolled into V1.6. It may end up as another configurable parameter: 1-2ms for full range or 0.5 - 2.5ms for full range.

________________________________________________